English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

Industry Knowledge

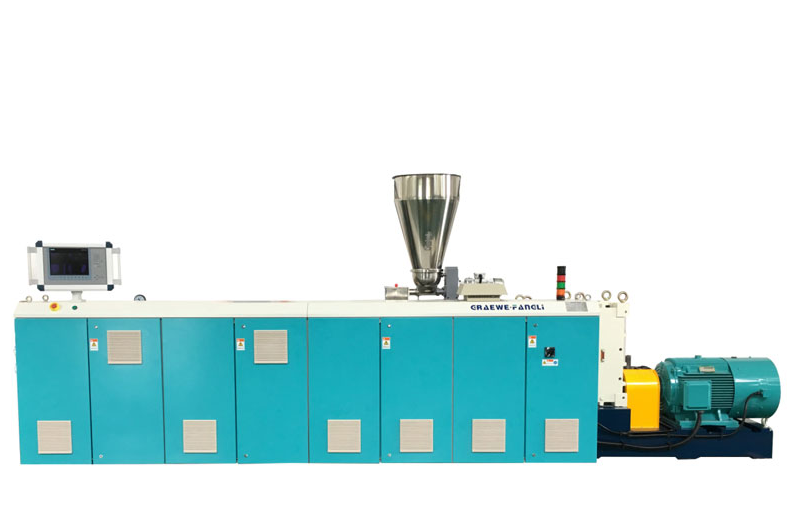

Development trend of precision plastic extruder

After more than 100 years of development, plastic extruders have been derived from the original single screw into twin-screw, multi screw, or even non screw and other models. The plastic extruder (main machine) can be matched with various plastic molding auxiliary machines such as pipe, film, holdin......

Read MoreMeasures to solve the unstable current of the main machine of plastic extruder

Reasons for the unstable current of the main machine of plastic extruder: (1) Uneven feeding. (2) The main motor bearing is damaged or poorly lubricated. (3) A section of heater fails and does not heat. (4) The screw adjusting pad is wrong, or the phase is wrong, and the components interfere.

Read MoreWhat is the function of the barrel? What are the characteristics of the structure?

What is the function of the barrel in the extrusion system? The barrel includes a screw, which rotates in the barrel. When the screw rotates and the thread is pushed, the heat is transmitted to the material by heating outside the barrel. In addition, the volume of the thread is gradually reduced,......

Read MoreOn the deceleration principle of twin screw extruder

In most extruders, the change of screw speed is realized by adjusting the motor speed. The driving motor usually rotates at full speed of about 1750 rpm, which is too fast for an extruder screw. If it rotates at such a fast speed, too much friction heat will be generated, and the uniform and well st......

Read MorePrinciple of twin screw plastic extruder

Firstly, the twin-screw extruder has the extruder principle of single screw extruder: solid conveying, melt pressurization and pumping, mixed stripping and devolatilization, but it is not simply so. The research of twin-screw extrusion theory began late, coupled with its many types, complex screw ge......

Read More