English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

Industry Knowledge

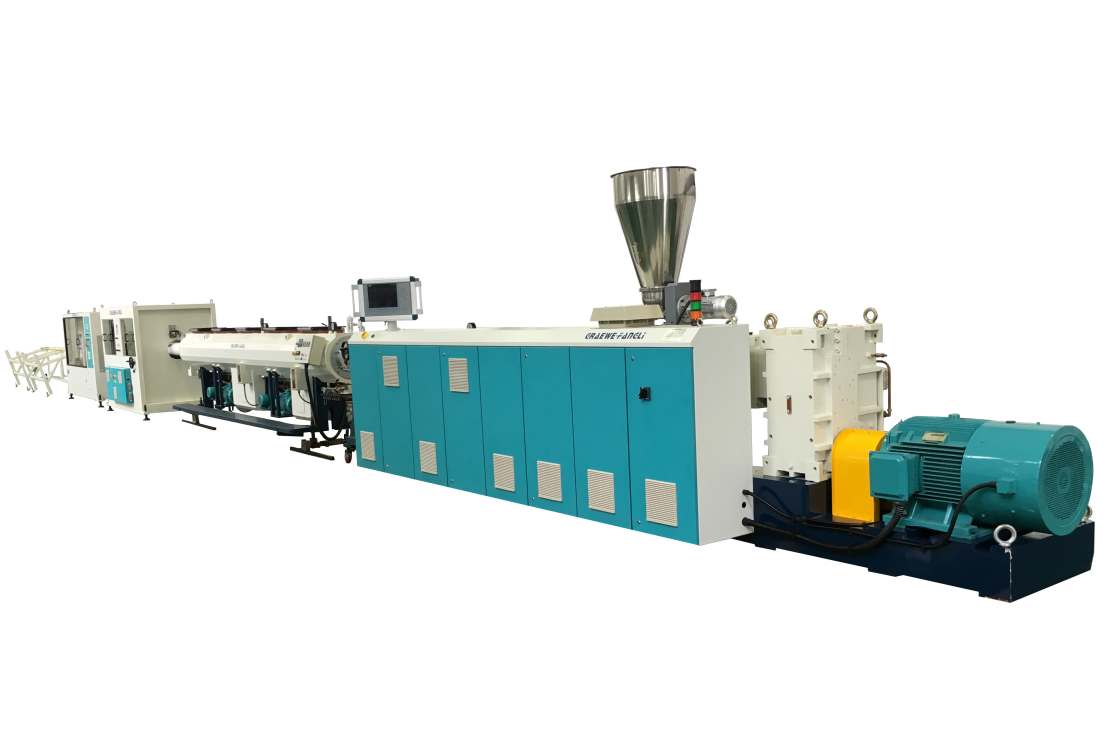

What are the advantages of PPR composite pipe production line?

PPR is the abbreviation of tripropylene polyethylene, also known as random copolymer polypropylene pipe. It adopts the method of hot fusion, has special welding and cutting tools, and has high plasticity. The price is also very economical. The thermal insulation performance is also very good, and th......

Read MoreThe manufacturer briefly talks about the basic manufacturing quality requirements of the screw used in the plastic extruder

Screw is the core equipment of plastic extruder equipment. It needs direct contact with plastic raw materials and will bear the working environment of high temperature, high pressure and high shear force for a long time. Therefore, our manufacturers will have high standards for the quality of screws......

Read MoreThe Principle and Application of Single Screw Extruder

As a common extruder equipment, the single screw extruder is used in plastic processing industry. What is its principle and structure? Below is the analysis for the single screw extruder from the extruder conveying section, compression section and metering section.

Read MoreSelection of heating and cooling methods for plastic extruder barrel

Heating and cooling are necessary conditions for plastic extrusion. In order to extrude plastics within the temperature range required by other processing technologies, the temperature of materials in the barrel of the plastic extruder is constantly adjusted by heating or cooling.

Read MoreScience Popularization on 9 Professional Technical Issues such as the Function and Configuration of Pipe Extruder

Recently, we collected the problems commonly encountered in the use of extruder functions and configurations, and invited relevant experts to give professional guidance to popularize these problems.

Read More