English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

Industry Knowledge

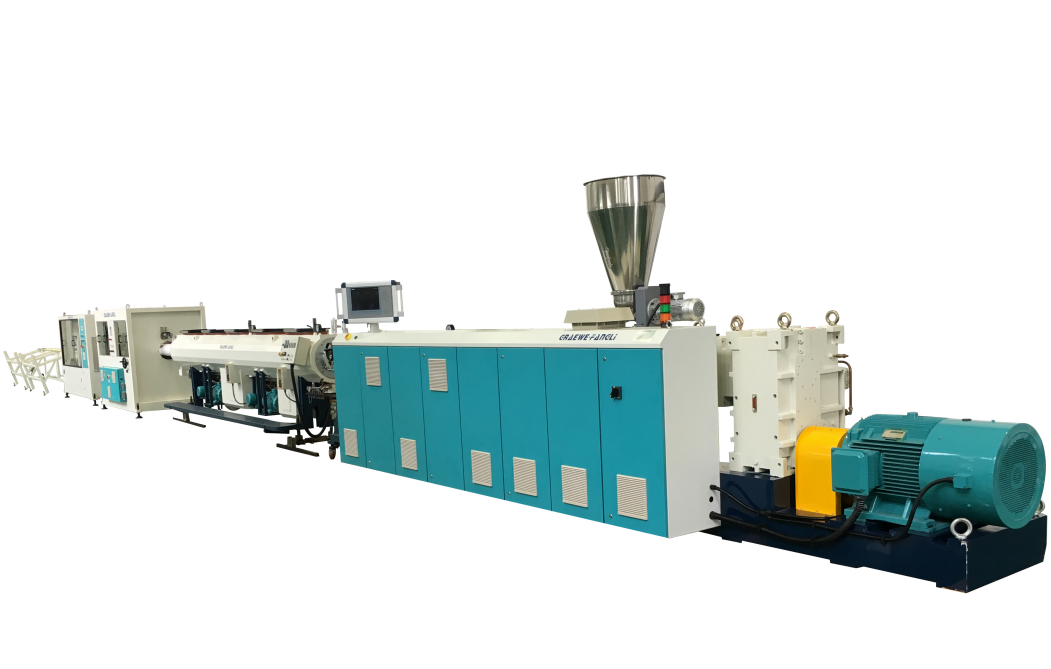

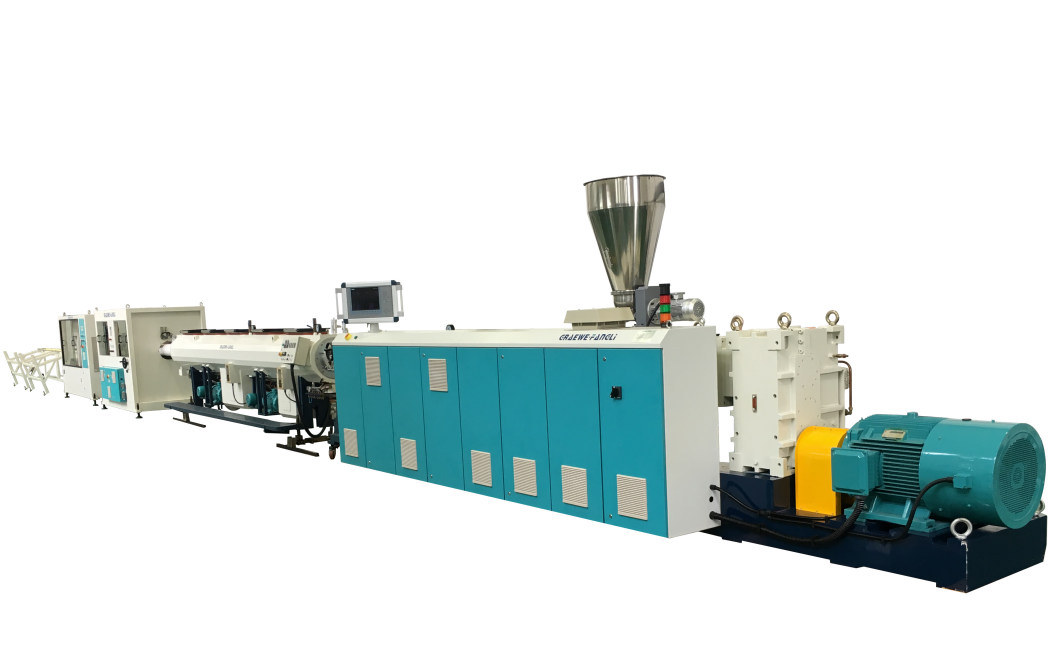

PERT (heat resistant polyethylene) high-speed production line

As plastic pipes, heat-resistant polyethylene not only has good stability, corrosion resistance and connection reliability compared with traditional metal pipes such as steel pipes and iron pipes, but also has the characteristics of energy saving, non-scaling, simple installation and convenient cons......

Read MoreTechnical Status and Development Trend of PVC-U Pipe

PVC-U pipe is a kind of plastic pipe with PVC resin as the main raw material and no plasticizer. Based on the characteristics of high strength, high modulus, good weather resistance, low density, acid and alkali corrosion resistance and electrical insulation, this material with a history of nearly 1......

Read MoreIn the Material Processing, Why Are Single-Screw Extruders Chosen in Some Cases While Twin-Screw Extruders Are Chosen in Others?

In the field of polymer material processing, extruders are undoubtedly a type of extremely critical equipment. Single-screw extruders and twin-screw extruders, as the two main types, each play important roles in different application scenarios relying on their unique performance characteristics. Tod......

Read MoreTake you to know the manufacturing process of CPVC power pipe equipment

CPVC power pipe produced by CPVC power pipe equipment is commonly used as cable protection pipe. The product has the characteristics of high strength, good flexibility, high temperature resistance, corrosion resistance, flame retardant, good insulation performance, no pollution, not easy to aging, l......

Read MoreA Comprehensive Guide to the "10 Core Components" of a Twin-Screw Extruder!

The twin-screw extruder is essential equipment in the production, modification, and processing of polymer materials. Whether it's modifying biodegradable materials like PLA and PBAT, filling and reinforcing PVC or PP, or preparing masterbatches and functional masterbatches, it is indispensable. Howe......

Read MoreChoosing the Right Screw L/D Ratio: Finding the Balance Point Between Quality and Cost

In the modified plastics production process, the screw length-to-diameter ratio (L/D) is a crucial parameter. It directly affects plasticization quality, production efficiency, and the performance of the final product. Understanding the intricacies of the screw L/D ratio can help us make more precis......

Read More