English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

News

Comparison Between Counter Rotating Conical Twin-screw Extruder and Parallel Twin-screw Extruder

Counter Rotating Conical Twin-screw Extruder; Parallel Twin-screw Extruder; extruder; plastic pipes; planetary cutting machine; Ningbo Fangli Technology; mechanical equipment manufacturer; plastic pipe extrusion equipment; PVC pipe extrusion line; PP-R pipe extrusion line, PE water supply/gas pipe e......

Read MoreFive Points for Attention in PVC Pipe Production

In the production process, since PVC is a kind of heat sensitive material, even if heat stabilizer is added, it can only increase the decomposition temperature and prolong the stable time without decomposition, which requires strict control of PVC molding temperature. Especially for RPVC, since its......

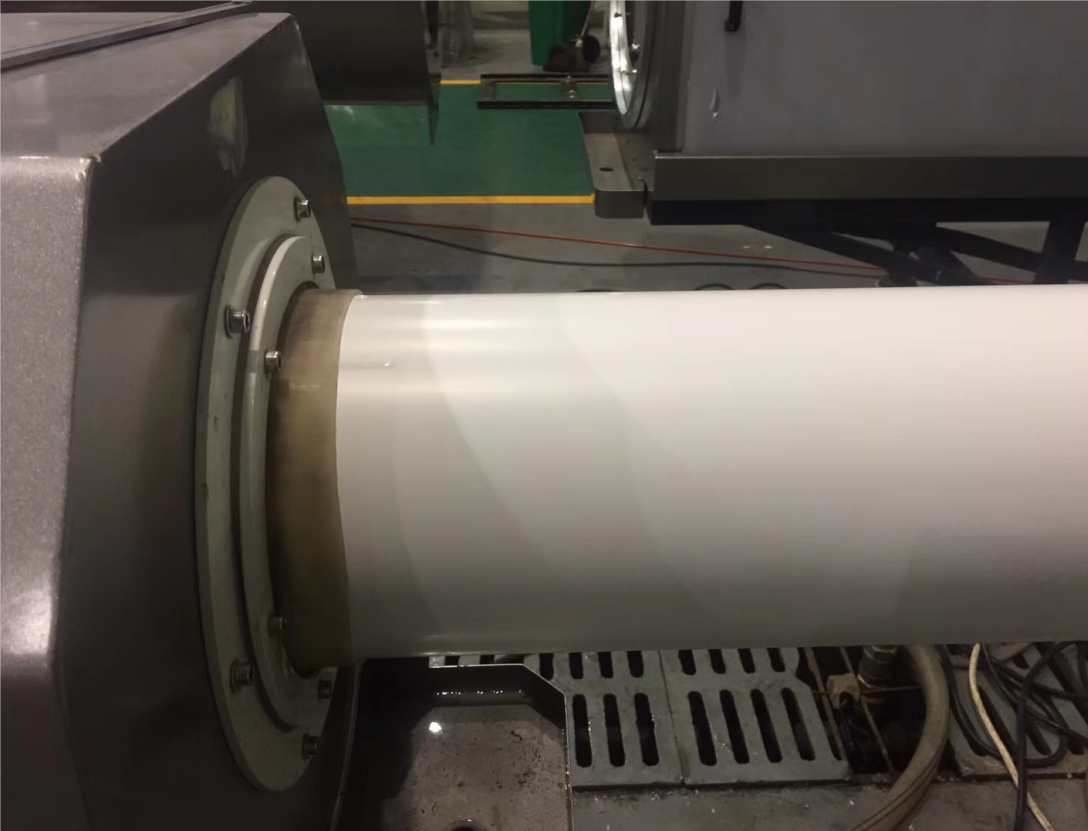

Read MoreProcess Control in PE Pipe Extrusion Process

The process of PE pipe production line Main production process: preparation of raw materials + additives → mixing → conveying and feeding → forced feeding → single screw extruder → extrusion head→ sizing sleeve → spray vacuum calibration tank → spray or immersion cooling tank →digital printer →belt......

Read More