English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

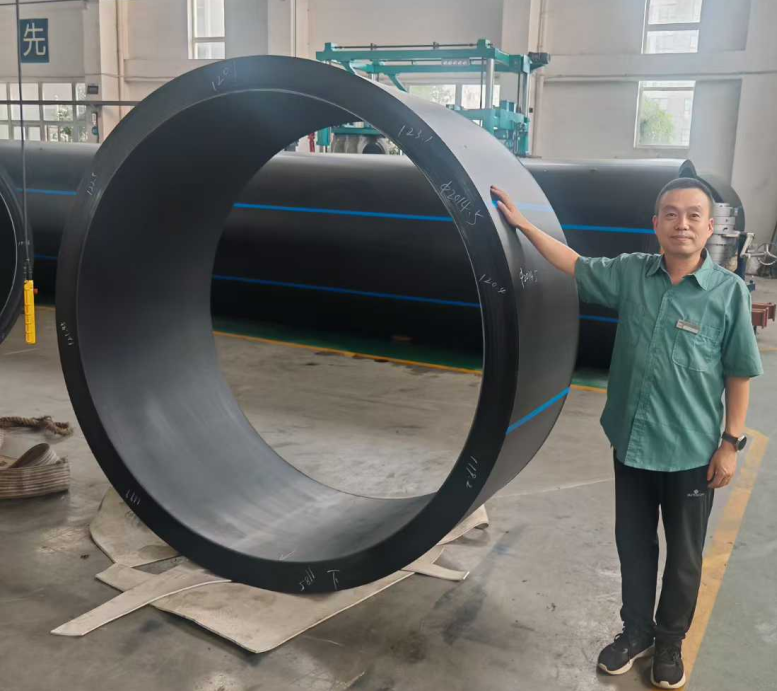

Fangli Currently Successfully Delivered a PE2000 Pipe Extrusion Production Line

2025-09-25

Ningbo Fangli Technology Co., Ltd. is a mechanical equipment manufacturer with over 30 years’ experiences of plastic pipe extrusion equipment, new environmental protection and new materials equipment. Since its establishment Fangli has been developed based on user’s demands. Through continuous improvement, independent R&D on the core technology and digestion & absorption of advanced technology and other means, we have developed PVC pipe extrusion line, PP-R pipe extrusion line, PE water supply / gas pipe extrusion line, which was recommended by the Chinese Ministry of Construction to replace imported products. We have gained the title of “First-class Brand in Zhejiang Province”.

The PE2000 high-speed extrusion set line is a high-end pipe production system integrating high output, low energy consumption, and intelligent control. The extrution line is exquisitely designed and superbly configured for the stable production of ultra-thick wall, high precision PE pipes. It is widely used in water supply, drainage, gas, nuclear power plant, mining, and other piping applications.

It can produce pipes with a wall thickness exceeding 150 mm, with energy consumption as low as 280 kWh per ton, significantly reducing production costs through high efficiency and energy savings. The finished pipes feature smooth inner and outer surface, and wall thickness deviation can be controlled within 70% of the national standard tolerance.

This extrusion line is configured with a 120-40 single-screw extruder incorporating the latest international technology. With a screw length-to-diameter ratio of 40:1, it ensures precise temperature control, uniform plasticization, and stable extrusion. It delivers an output exceeding 2300 kg/h. It is suitable for extrusion of various raw materials, and is capable of producing large-diameter, ultra-thick-wall pipe for water supply and nuclear power applications.

The extruder is equipped with internationally renowned components, including a WEG motor, an ABB frequency converter, Taiwan Sunlung heavy-duty gearbox, INOEX gravimetric dosing system, and Siemens control and display system.

The Die technology integrates five Fangli patents, including "A Center Air Extraction Type Flow Channel for Plastic Pipe Extrusion Die" (Patent No. ZL202420437244.5). Its external manifold and center air extraction achieve an optimal balance between efficient inner cooling and reduced flow resistance. A triple dead-zone-free wall thickness adjustment structures enhances anti-sag performance for thick-wall pipe production. Air-cooling mold core temperature control with heat recovery technology reduces carbon emissions, ensuring environmental friendliness.

The stackable bushing and mandrel technology facilitates quick size changes. The color mark ring is positioned near the bushing enalbes rapid stripe extrusion and production of qualified pipe, effectively saving raw material.

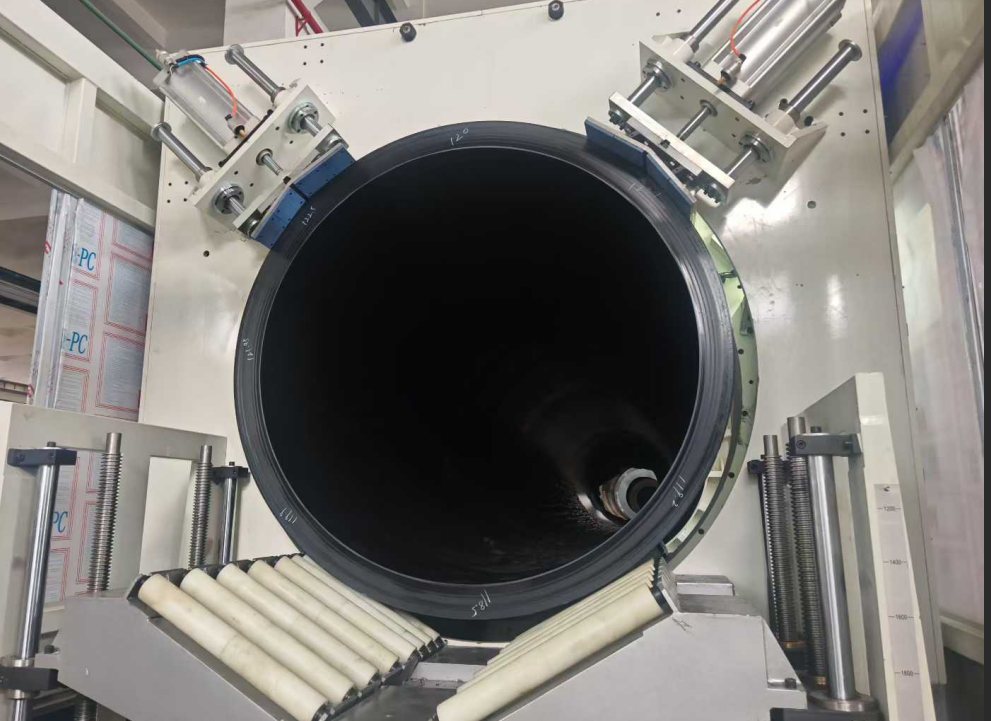

The vacuum calibration unit employs a three-tank combined design featuring independent vacuum and water temperature control, segmented sizing and cooling, and a frequency conversion constant-pressure vacuum system. Its separation/combination function allows rapid online inspection, controlling pipe ovality within 60% of the national standard.

The haul-off tractor features an extended and widened design with 20 caterpillar tracks. Each track is independently servo-driven for high synchronization, providing traction force up to 20 tons to meet stringent nuclear pipe production requirements.

The cutter utilizes patented gantry-type dual-track electric feed cutting technology and a high-strength cutting chamber, suitable for chipless cutting of heavy-load, ultra-thick-wall pipes. Maximum cutting wall thickness is 170 mm, with smooth cutting surface.

If you need more information, Ningbo Fangli Technology Co., Ltd. welcomes you to contact for a detailed inquiry, we will provide you with professional technical guidance or equipment procurement suggestions.