English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

Industry Knowledge

Three-layer Composite PP Pipe Extrusion Line

Pipe has three layers to provide the highest mechanical performance: 1.External black PP layer provides excellent impact resistance and long-term UV protection; 2.Intermediate PP-MD layer provides high mechanical resistance and excellent sound proofing performance; Internal layer low-friction, wh......

Read MoreProfessional manufacturers share you how to improve the life of plastic extruder screw

Screw is one of the core parts of the plastic extruder equipment. When we use extruder normally, the life of screw can sometimes restrict the service life of the equipment. So we need to know how to improve the life of the screw in the extruder.

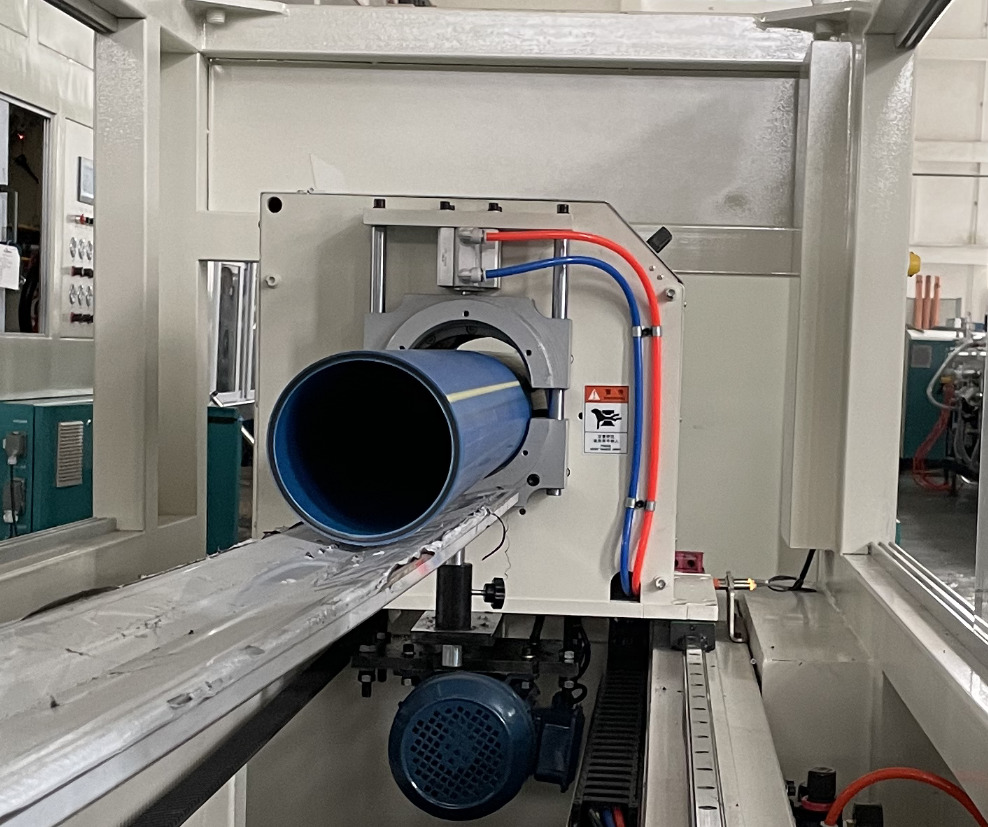

Read MoreHow to choose cutting machine for pipe production in the extrusion line

The extruder production line can continuously produce plastic pipes. Because the pipe production is uninterrupted, and the pipe has a fixed length specified in the standard, in order to ensure the standard length of the pipe, we need to use the cutting machine as an auxiliary equipment to cut the pi......

Read MoreType of Haul-Off

In the process of extruding pipe, the pipe diameter and wall thickness can generally be adjusted by changing the traction speed. Therefore, in production, the traction of pipe is required to be uniform and stable, and the traction speed adjustment is convenient and sensitive, so as to ensure the uni......

Read More